Winter conditions pose unique challenges for ventilation

16.02.2026

Severe frost conditions also present specific challenges for building ventilation. High-efficiency heat recovery combined with moist exhaust air can, in extreme cases, pose safety risks.

The primary task of ventilation is to supply buildings with fresh air and remove excess moisture from indoor air. Humans generate moisture simply by breathing, and, especially in residential buildings, by drying laundry, cooking, and washing. This is referred to as the moisture load of a space, which ventilation is designed to control.

Insufficient ventilation increases indoor humidity. This insufficiency may be caused by dirty filters in the air handling unit, by setting the ventilation rate too low, or by switching it off entirely, in an attempt to save energy or reduce draught from supply air.

During the first years of a building’s use, construction moisture trapped in the structures is also released into the indoor air, further increasing the moisture load.

When moist indoor air is extracted through a high-efficiency heat recovery system into the exhaust air duct, the air temperature can drop well below freezing. In such conditions, moisture either sublimates directly into ice on the cold surface of the exhaust air device or condenses into water, which then freezes.

Over time, ice accumulating on the exhaust air device’s surfaces increases pressure loss and begins to restrict exhaust airflow. This can lead to overpressure inside the space. Overpressure relative to outdoor air may cause fogging on the inner surface of the outermost window pane and, eventually, freezing.

A frozen exhaust air diffuser can also form large icicles that may fall from heights of several tens of meters down to street level. At that point, the issue becomes a serious safety risk.

The new RVN keeps ice away and ventilation efficient

Preventing ice accumulation has recently been a key driver in the development of exhaust air devices. Cold air combined with a humid environment, such as near bodies of water, is the most typical combination causing problems.

ETS NORD has launched a new combined outdoor air and exhaust air unit designed specifically for demanding Nordic conditions.

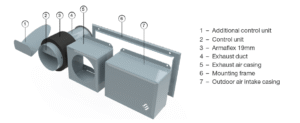

In the new RVN device, special attention has been paid to improving the thermal insulation of the exhaust air path. As a result, ice does not form on the exhaust side even in the most challenging winter conditions. The exhaust duct is equipped with 19 mm Armaflex thermal insulation, which reduces heat loss and the risk of condensation while maintaining stable airflow and reliable operation in cold, humid environments.

Figure 1. The structure of the RVN and its individual components.

The exhaust air discharge section of the RVN has also been designed to be more streamlined and aerodynamic, minimizing pressure loss. This, in turn, reduces the air handling unit’s energy consumption.

The exhaust air control section has been further developed. On the exhaust side, there are three adjustable elements that control air velocity through the louvers. This enables the required 5 m/s exhaust-air discharge velocity to be achieved across varying airflow rates.

Based on conducted icing tests, it can be concluded that no ice accumulates on the surface of the RVN even under the most severe winter conditions.

Figure 2. The RVN 3D CFD simulation model shows that a long exhaust air throw effectively prevents mixing of outdoor and exhaust air.

For more information contact our specialists

Kadi Alber

Head of Product Management

NORDduct, NORDsilencer, NORDexternal, NORDdoor, NORDdiffuser, NORDdamper & NORDgrille

Tuukka Karlsson

Product Group Manager

NORDexternal, NORDduct, NORDsilencer, NORDdoor, NORDdiffuser & NORDgrille